Ngaphezu kweminyaka eyishumi yokuqongelela ubuchwepheshe kanye namakhasimende, i-Techik izinikela ocwaningweni nasekuthuthukisweni okuqhubekayo.Isizukulwane esishaI-Bulk Product X-ray Inspection Systemmanje izuza ukuqashelwa okwengeziwe kumakhasimende ethu.

Ukuthuthukiswa kwesofthiwe

Isofthiwe yesikhathi sangempela

Isofthiwe yesikhathi sangempela ingagwema iphutha lesikhathi elibangelwa amawindi.Isikhathi sokuvunguza komoya singancishiswa sisuka esikhathini sokuqala sokuvula esingu-50ms siye ku-5-10ms samanje, futhi ukukhishwa kokungcola kuyingxenye eyodwa kwezintathu yokoqobo.

Ngaphandle kwalokho, i-algorithm yokukhetha umumo kanye nesofthiwe yokuhlunga amantongomane ayatholakala uma udinga ukusebenza okungcono.

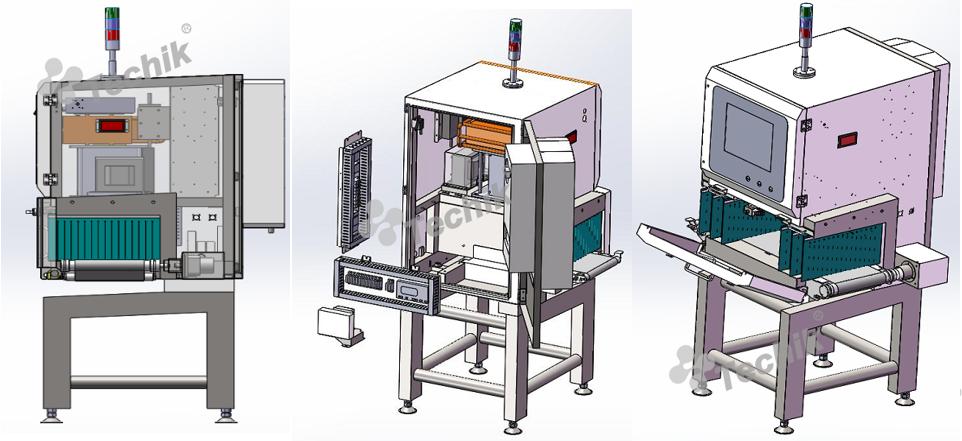

I-Modularized Structure Design

Ukwakheka kwesakhiwo se-modular kwenza ingxenye eyodwa ifanele amamodeli ahlukahlukene, angathuthukisa ukusebenza kahle kokukhiqiza ngo-30% - 40%.Umkhiqizo uhlanganiswe kakhulu okwenza ukunakekelwa kube lula futhi kunciphisa kakhulu izindleko zokusebenza nokugcinwa kwamakhasimende, njengebhande le-conveyor kanye nedivayisi yengalo.

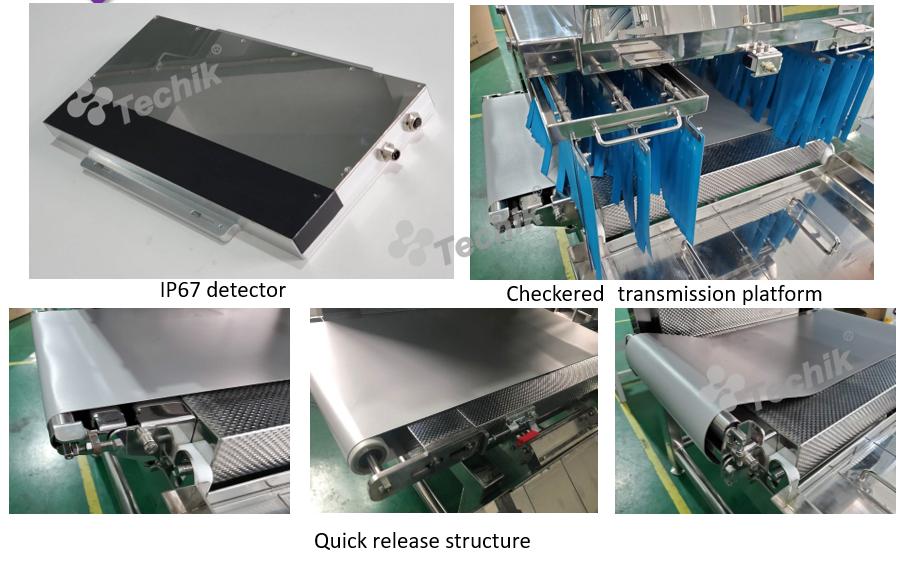

Idizayini Yenhlanzeko Yezinga Eliphezulu

I-X-ray eningi ifakwe ama-flange athambile ukuvimbela izinto ukuthi zingaweli esikhaleni sebhande, njengelayisi, ubhontshisi obomvu nokunye ukudla okuyimbudumbudu, okungagcini nje ukunciphisa ukusetshenziswa kokudla, kodwa futhi kunciphise inkathazo yokuhlanza umshini, ukuze ukufeza izinga eliphakeme lokuklama kwenhlanzeko.

1.Umklamo wonke wemithambeka uvumela indle ukuthi igeleze phansi ngomsele ngokwemvelo.

2.Awekho amakhona ahlanzekile, ayikho indawo yokuzalela amagciwane;

I-3.Umklamo ovulekile womshini wonke ulungele ukuhlanza nokuhlanza kunoma yisiphi isikhundla ngaphandle kwemishini;

4.Equipment kungenziwa hashazwa ngqo futhi zihlanzwe;

5.Ngomklamo we-Modularized, ingxenye yomshini wokuhambisa umshini, ikhethini elithambile elivikelayo, njll lingahlakazwa kalula.

Ukuthuthukiswa kwesakhiwo sejeneretha nomtshina

1.Indawo yokufaka ijeneretha kanye nendawo yokufaka umtshina ohambisanayo kulungiswa kubheke lapho umoya uphephetha khona.Ngesivinini esiphezulu esingu-120m/min, ibanga elisebenzayo phakathi kwembobo yokubona kanye nengxenye ephephetha umoya lifinyezwa libe ngumkhawulo.

2.Ibanga phakathi kwembobo yokuphakela kanye nembobo yokuthola liyakhuphuka, ukuze umkhiqizo ube nebanga elide lokusheshisa kanye nesikhala esizinzile.

3.Ibanga phakathi kwembobo yomtshina kanye nomlomo womoya liyancishiswa, ngakho amathuba kanye ne-amplitude yokunyakaza okungazinzile komkhiqizo ngemva kokutholwa kuyancishiswa futhi ukunemba kokwenqaba kuyanda.

4.Ngokusebenzisa i-valve ye-solenoid enezimbobo ezingu-9, umlomo wombhobho womoya omusha kanye nepuleti lokukhweza, ijethi yomoya yomhubhe engama-72 ingafakwa emshinini wamamodeli angama-40 ngaphandle kokushintsha ipuleti lokukhweza.

5.Enqubweni yokwenqatshwa, indawo yokulahla ye-nozzle eyodwa incane, futhi isilinganiso sokwenza nokunemba kuthuthukiswa kakhulu.

Isikhathi sokuthumela: Jul-23-2022