Date: June 24-26, 2025

Location: National Exhibition and Convention Center (Shanghai)

Booth: 51E05

Techik invites you to the ProPak China & FoodPack China 2025, the premier event for food processing and packaging machinery, held from June 24-26, 2025, at the National Exhibition and Convention Center in Shanghai. Visit us at Booth 51E05 to explore our cutting-edge full-stack ultra-high-definition equipment and innovative solutions, driving the future of intelligent and digitized food production lines.

Discover Techik’s Advanced Solutions

Techik will showcase a suite of state-of-the-art technologies tailored for the food industry, focusing on four key areas: detection, sorting, grading, and analysis. Our solutions ensure unparalleled quality control and efficiency across diverse food processing applications.

Applications at a Glance

Detection: Seal integrity, inkjet printing, shrink film, foreign object, and weight inspection.

Sorting: Color/shape anomalies, surface texture, defect, and reject sorting.

Grading: Weight, shape, material, and appearance classification.

Analysis: Product composition analysis for precise quality assurance.

Highlighted Solutions and Equipment

1. Ultra-HD Bulk Material Detection

Application: Nuts, seeds, dried fish, edamame, and more.

Case Study: Hazelnuts – Accurately detects fine foreign objects (e.g., screen mesh, plastic, shells) and internal defects (e.g., shrinkage, mold, calcification, insect damage).

Equipment: Ultra-HD Bulk X-Ray Inspection System

Ultra-clear imaging for low-density and organic contaminants.

AI-powered algorithms for high-efficiency defect detection.

Multi-lane detection and rejection to minimize material loss.

2. Ultra-HD Dual-Energy Detection & Analysis

Application: Solves challenges in meat processing, such as residual bone detection and fat content analysis, while addressing low-density/thin contaminants and frozen product stacks.

Case Study: Frozen chicken – Identifies residual bones, fishbones, sand, and thin contaminants (e.g., aluminum, glass, PVC).

Equipment: Ultra-HD Dual-Energy X-Ray Inspection System

High-precision detection with robust compatibility across diverse products.

Durable, reliable, and long-lasting performance.

3. Ultra-HD Seal Inspection

Application: Small and medium-sized packaged foods with aluminum foil, metallized film, or PE film.

Case Study: Plastic/aluminum foil snack bags – Detects seal leaks, inclusions, wrinkles, and more.

Equipment: Ultra-HD X-Ray Inspection System for Sealing Stuffing and Leakage

Comprehensive inspection for seals, foreign objects, defects, and weight.

Identifies issues like minor leaks, wrinkles, damage, and insect contamination.

4. Ultra-HD Multi-Beam Bottle/Can Detection

Application: Bottled beverages, condiments, canned nutritional powders, and luncheon meat.

Case Study: Canned products – Eliminates blind spots in complex areas like can bottoms, screw caps, and pull-tabs.

Equipment: Ultra-HD Multi Beam X-Ray Inspection for Cans, Bottles and Jars

High-speed, high-precision detection with complementary beam angles.

Real-time monitoring for line congestion, product falls, and rejecter air pressure, with alarms for defects and overfilled bins.

5. Ultra-HD Multi-Angle Bulk Sorting

Application: Frozen, fresh, freeze-dried, fried, baked, high-moisture, or high-sugar bulk foods.

Case Study: French fries – Detects hair, scab disease, rot, and green heads.

Equipment: Ultra-HD Multi-Beam Optical Sorter

Eliminates visual blind spots and enhances detection of subtle color differences and defects.

High IP rating with easy-clean design for hygiene and maintenance.

6. Ultra-HD High-Protection Equipment

Application: Packaged products requiring rigorous cleaning.

Equipment: IP69K Ultra-HD X-Ray Inspection System

Withstands high-temperature, high-pressure water/steam cleaning.

Superior detection of fine contaminants and internal defects.

7. High-Speed, High-Precision Weight Sorting

Equipment: New High-Speed Checkweigher

High accuracy, smooth product handling, and durable design.

Easy part replacement and intuitive 10-inch HD touchscreen interface.

Compact, High-Efficiency Equipment

8. Standard X-Ray Inspection System

Compact design (50% smaller than conventional models).

Easy to operate, ideal for space-constrained environments.

9. Compact Vision Inspection System

Detects defects in inkjet characters, labels, barcodes, and QR codes on bags, boxes, bottles, and cans.

Easily integrates into existing production lines.

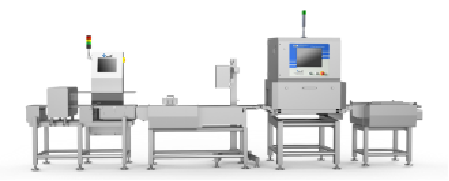

10.Combo Metal Detector and Checkweigher

Combines metal and weight inspection in a single cantilever frame, saving space and enhancing efficiency.

All-in-One Finished Product Inspection Solution

Visit Us at Booth 51E05

Join Techik at ProPak China & FoodPack China 2025 to experience how our ultra-HD, intelligent solutions are transforming food safety and quality control. Let’s discuss the future of smart, digitized food production together!

For more details, contact us or visit us at the National Exhibition and Convention Center, Shanghai, from June 24-26, 2025. We look forward to seeing you at Booth 51E05!

Post time: Jun-18-2025