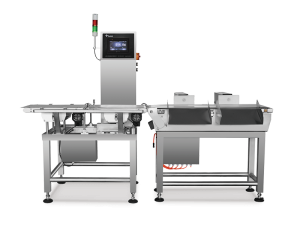

Smart Nut Peanut Coffee Bean Color Sorter/Color Separator/Beans Sorting machine

*Ensuring pure and safe food with Advance Sorting Technology!

CCD sensor based belt type Color Sorter; Low broken rate; Heavy load production; Advance algorithm and high Sorting Accuracy!

In commitment to substantial investment in R&D ensures the technology of Techik products leading the industry. Techik belt sorting machines are able to detect and remove the most challenging defects!

|

CONFIGURATION & TECHNOLOGY |

|

| Ejector | 63/126/189/252 |

| Smart HMI | True Color 15” Industrial Human Machine Interface |

| Camera | High resolution CCD; Industrial wide-angle LENs; Ultra-clear imaging |

| Intelligent Algrithm | Own proprietary industrial leading software and algrithm |

| Simultaneous Grading | Strong simultaneous color sorting+ sizing and grading capabilities |

| Consistency and Reliability | Featuring broadband cold led illumination, long-life serviceable ejectors, Unique optical system, the MULTIFUNCTION SERIES sorter delivers a consistent sorting performance and reliable operation in the long run |

| Advantage | Much more broader application than chute sorter, suitable for fragile, irregular, wet commodities. |

*Parameter

|

Model |

Voltage |

Power (kw) |

Executing Unit |

Air Consumption (m3/min) |

Throughput (t/h) |

Net Weight (kg) |

Dimension (LxWxH) (mm) |

|

TCS-300S-S |

180~240V,50HZ |

1.5 |

63 |

≤2.0 |

0.7~1.3 |

950 |

3780x1270x1915 |

|

TCS-600S-S |

2.0 |

126 |

≤2.5 |

1.0~2.6 |

1100 |

3780x1580x1915 |

|

|

TCS-900S-S |

2.5 |

189 |

≤3.0 |

2.0~4.0 |

1250 |

3780x1890x1915 |

|

|

TCS-1200S-S |

3.0 |

252 |

≤3.6 |

3.0~6.0 |

1400 |

3780x2200x1915 |

|

|

Note |

The parameter based on test results on peanut with around 2% contamination; It varies depending upon different input and contamination. | ||||||

*APPLICATION

*Packing

*Factory Tour