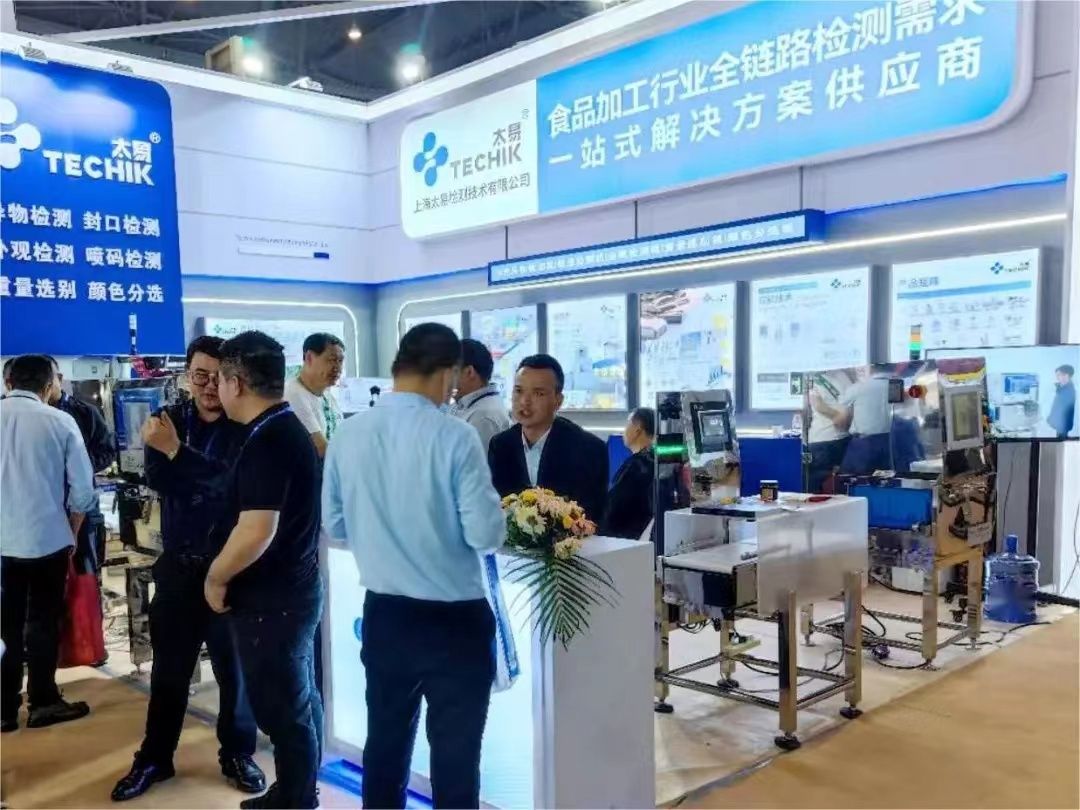

The 108th China Food and Drinks Fair opened grandly in Chengdu, during April 12-14, 2023! During the exhibition period, the professional team of Techik (Booth No. 3E060T, Hall 3) brought various models and solutions such as intelligent X-ray foreign matter inspection system, metal detector, checkweigher, etc.

A variety of Techik equipment exhibited, showing specific solutions

2023 China Food and Drinks Fair brought together 6,500+ domestic and foreign exhibitors, and the scene was full of popularity. This exhibition, Techik brought food and beverage enterprises detection and inspection equipment and solutions in various production stages such as raw material acceptance, processing on-line testing, packaging, etc.

For various foods and beverages such as candy, chocolate, luncheon meat, self-heating rice, hot sauce, beer, juice, etc., Techik can tailor a professional, one-stop detection and inspection solution.

Multi-directional, multi-functional, intelligent protection of food quality

A variety of Techik intelligent X-ray inspection equipment in the booth features high precision and multiple functions, which can protect the "smart" manufacturing and quality safety of food from raw materials to finished products.

Techik dual-energy intelligent X-ray inspection equipment in the booth can be equipped with dual-energy high-speed high-definition TDI detectors and AI intelligent algorithms. The machine is easy to operate and has strong product adaptability. The dual-energy intelligent X-ray inspection equipment can realize shape + material detection, helping to solve detection problems such as low-density foreign matter and thin foreign matter (such as thin foreign matter made of aluminum, glass, PVC, etc.).

Techik intelligent X-ray inspection machine is suitable for small and medium-sized packaging, low-density and uniform products. Techik intelligent X-ray inspection machine can fully detect physical pollutants such as metal and glass, with the characteristics of low energy consumption and compact design.

For packaged beef jerky, dried tofu and other snack foods, Techik X-ray inspection machine for sealing, leakage and stuffing has added the detection function for sealing oil leakage and sealing material on the basis of the original foreign object detection function, which can be used for various packaging such as aluminum foil, aluminized film, plastic film, etc.

Techik intelligent bulk X-ray inspection machine is suitable for bulk nuts, roasted seeds and nuts, bulk candy and other materials. The machine can not only identify metal, glass, straw and other miscellaneous and organic impurities, but also identify defects, insect erosion, and shriveled nuts. and other raw material defects.

Metal detector and checkweigher with strong versatility and wide application range

Metal detectors and weight sorting machines are widely used in the food and beverage industry. The models displayed at Techik booth can be applied to a variety of food and beverage production lines.

The IMD series metal detectorsin the Techik booth are equipped with dual-channel detection, phase tracking, product tracking, automatic balance correction and other functions. The detection accuracy is higher and more stable, and it can be applied to products with complex components and various types.

Techik IXL series weight sorting machine is suitable for products with small and medium packages. It adopts high-precision sensors and can realize dynamic weight detection with high speed, high precision and high stability.

In response to the whole-link detection needs of the food processing industry, Techik can rely on metal detectors, weight sorting machines, intelligent X-ray foreign object detection machines, intelligent visual inspection machines, intelligent color sorting machines and other diversified equipment matrices to create a comprehensive range of products for customers. From the raw material section to the finished product section, a one-stop inspection solution helps to solve various quality problems such as foreign matter, color, shape, overweight/underweight, oil leakage, product defect, inkjet character defect, heat shrinkable film defect, etc. , to help enterprises move towards a broader space.

Post time: Apr-15-2023