X-Ray Inspection System for Package Sealing, Stuffing and Oil Leakage

Thechik® — MAKE LIFE SECURE AND QUALITY

X-Ray Inspection System for Package Sealing, Stuffing and Oil Leakage

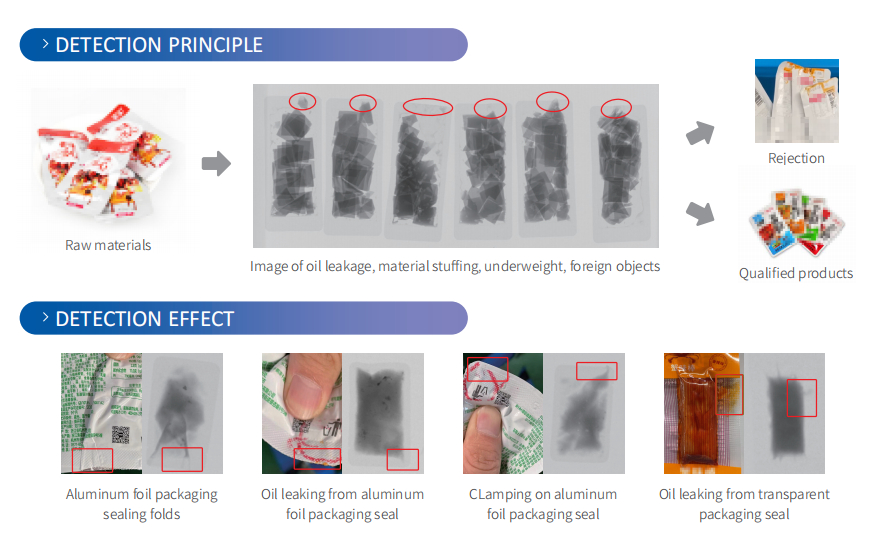

The snack food industry faces substantial challenges with sealing and material containment, often resulting in “leak oil” issues that compromise product quality and increase the risk of contamination and spoilage. To tackle these persistent problems, Techik introduces its X-Ray Inspection System for Package Sealing, Stuffing and Oil Leakage, a solution engineered to ensure optimal sealing and prevent oil leakage across various packaging formats, including aluminum foil, plastic, small and medium bags, and vacuum-sealed packages.

Equipped with high-resolution X-Ray imaging, the system precisely detects and identifies abnormalities in the sealing process, such as material clamping errors, that commonly lead to oil leakage. Its intelligent capabilities provide real-time monitoring and immediate identification of compromised packaging, thereby reducing the likelihood of contamination and enhancing the shelf life of products. The X-Ray Inspection System's advanced technology thoroughly examines and analyzes the integrity of packaging materials, securing a higher level of safety and efficiency in snack food processing. By addressing the core challenges of stuffing, sealing, and leakage, Techik's system represents a sophisticated and reliable tool to improve both product quality and operational efficiency.

Video

Applications

X-Ray Inspection System for Package Sealing, Stuffing and Oil Leakage developed by Techik finds extensive application across various industries that rely on packaging and quality control. Some of the key industries where this machine is commonly utilized include:

Food and Beverage Industry: The X-Ray Inspection System plays a crucial role in ensuring the integrity of packaging in the food and beverage sector. It helps detect foreign objects, such as metal fragments or contaminants, while also identifying issues related to sealing, stuffing, and leakage in different types of packaging materials.

Pharmaceutical Industry: In pharmaceutical manufacturing, maintaining the quality and safety of packaged products is of paramount importance. The X-Ray Inspection System aids in verifying the accuracy of drug packaging, detecting any irregularities in sealing, and ensuring compliance with industry regulations.

Cosmetics and Personal Care Industry: Cosmetics and personal care products require reliable packaging to preserve their quality and prevent contamination. The X-Ray Inspection System assists in identifying issues related to sealing integrity, ensuring that products meet

Overall, the X-Ray Inspection System has a wide range of applications in industries where packaging quality and integrity are crucial for product safety, compliance, and consumer satisfaction.

Advantage

Contaminants Detection

Contaminants: metal, glass, stones and other malignant impurities; plastic flakes, mud, cable ties and other low-density pollutants.

Oil Leakage & Stuffing Detection

Accurate rejection for oil leakage, stuffing, oily juice contamination, etc.

Online Weighing

Contaminants inspection function.

Weight checking function, ±2% inspection ratio.

Overweight, underweight, empty bag. etc. can be inspected.

Visual Inspection

Visual inspection by supercomputing system, to check product packaging appearance.

Wrinkles at the seal, skewed press edges, dirty oil stains, etc.

Flexible Solution

Exclusive and complete solutions can be customized according to customer needs.

TIMA Platform

TIMA platform, integrating R&D concepts such as high sensitivity, low energy consumption, low radiation, intelligent algorithms, and high hygiene level.

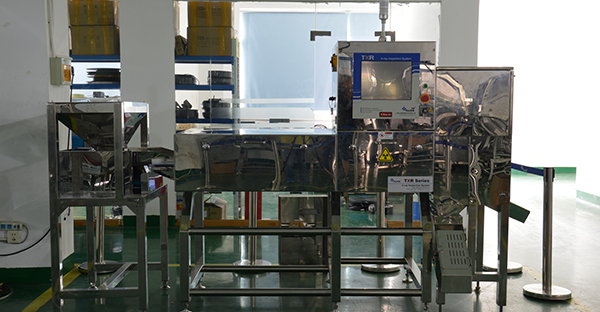

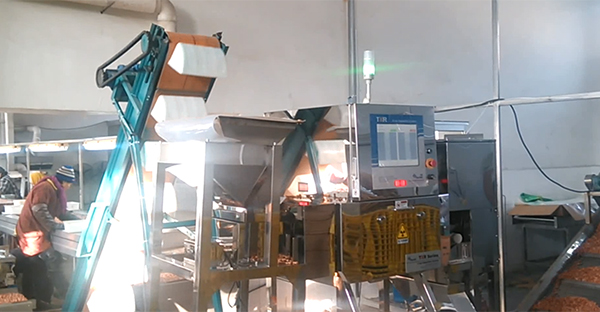

Factory Tour

Packing