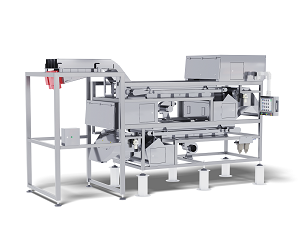

Intelligent Visual Color Sorter Visual Sorting Equipment

*Techik Intelligent Visual Color Sorter Visual Sorting Equipment Introduction

Foreign impurities like hair, low yield, and greasy dust have persistently troubled the sorting process of high-moisture, oily, and delicate food items. Techik's Intelligent Visual Color Sorter Visual Sorting Equipment has undergone significant enhancements in its fundamental hardware, software, and structural blueprint. This advanced system can effectively segregate dehydrated vegetables, fresh produce, frozen vegetables, seafood, expanded snacks, and delicate nut kernels (such as walnuts, almonds, cashews, pine nuts, etc.), thereby assisting enterprises in addressing sorting issues related to minor defects and unwanted hairy impurities. Moreover, it features a rapid disassembly and cleaning mechanism and adopts a high-grade sanitary design, facilitating easy cleaning and maintenance and contributing to the enhancement of the overall workshop environment.

*Why Techik Intelligent Visual Color Sorter Visual Sorting Equipment?

1. Through deep learning algorithms, extensive data model training, and an intelligent cloud platform, one-click visual sorting solutions can be swiftly developed based on diverse sorting requirements, enabling efficient, unmanned sorting, thereby enhancing sorting line efficiency and quality.

2. Intelligent matching of rejection methods based on real-time material information, including material trajectory, posture, spatial location, and speed, not only ensures accurate targeting and prevents material splashing and contamination but also effectively reduces air valve gas consumption and extends their lifespan.

3. Utilizing internal self-checking programs and detection mechanisms, the equipment's automatic dust removal system, spray valves, filter cores, and other components undergo intelligent cyclic self-inspections, optimizing the sorting process, enhancing equipment stability, and user convenience.

*Techik Intelligent Visual Color Sorter Visual Sorting Equipment Advantages

1. Reduced operational costs for enterprises: With the support of ultra-high-resolution imaging systems, multi-spectral detection systems, and AI intelligent algorithms, it accurately identifies product flaws and foreign materials. It can replace manual labor in removing hair, feathers, thin ropes, etc., helping processing companies reduce manual sorting costs and overcome minor impurities.

2. Achieve more efficient sorting: Substantial improvement in conveying speed. Based on material anti-breakage settings, the conveying system speed can reach 90m/min, aiding enterprises in achieving higher production and increased profits.

3. Simple and easy operation: With a high level of waterproof and dustproof capabilities and a rapid disassembly design, it can be cleaned of dirt within minutes, contributing to improving workshop conditions.

4. More stable sorting effects: This equipment adopts modular design, with modules featuring good interchangeability, easy maintenance, and upgrades. Modules can also be combined and configured according to customer needs, providing greater efficiency, stability, and cost-effectiveness.

*Techik Intelligent Visual Color Sorter Visual Sorting Equipment Features

AI Easy Sorting: Utilizing AI deep learning technology, one-click activation of AI intelligent sorting.

Ultra-high-definition imaging: Recognition accuracy of 0.0004mm³, capable of identifying subtle foreign objects such as hair.

Increased speed: Conveying speed up to 90m/min, handling larger volumes for higher output. Taking roasted peanuts as an example, it can process approximately 2-3 tons per hour.

Efficient rejection: Intelligent rejection based on geometric center positioning, preventing breakage, splashing, and minimizing losses.

*Packing

*Factory Tour